Would you like to get notifications from Christian?

What happened?

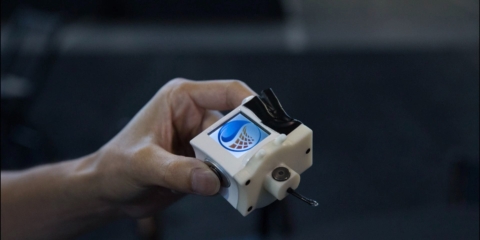

Traditionally, additive manufacturing has been used in the aerospace industry to print small metal parts, such as brackets and fuel nozzles. But, Relativity Space Inc. hopes to change that scenario by thinking big. The start-up company plans to print entire rockets using state-of-the-art technology. Relativity Space recently acquired a 1-million-square-foot factory in Long Beach and transformed the facility into a “factory of the future” centered around Stargate, a machine developed in-house that it claims is the world’s largest 3D printer. The company has also invested in state-of-the-art artificial intelligence technology and robots to boost production efficiency.

Read the entire article: https://bit.ly/3KXOqAa

Why is this important?

“By fusing 3D printing, artificial intelligence, and autonomous robotics, we are pioneering the factory of the future,” says Tim Ellis, CEO of Relativity Space. “Disrupting 60 years of aerospace, [we] offer a radically simplified supply chain, building a rocket with 100 times fewer parts in less than 60 days.” Because of additive manufacturing technology, Ellis expects to reduce the part count on a typical rocket from 100,000 to 1,000 components. The company’s six-axis robots can emit about 10 inches of material onto a large turntable fixture every second. The directed energy deposition printing process uses proprietary alloys designed to meet mission-critical performance requirements. Ellis wants to disrupt and revolutionize the traditional way of mass-producing rockets. In the past, the slow production process has relied on complex supply chains, large factories, fixed tooling, and extensive manual labor. The entire assembly process typically takes two years or more. With his new production paradigm, Ellis intends to reduce the development cycle from 48 months to six months and the actual build time from 24 months to two months.

Christian is a futurist and trendwatcher who speaks about the impact of exponential technologies like AI on organizations, people, and talents. Christian tailors his presentations to your audience's specific industries and needs.

Our world is changing at an exponential rate! A big tidal wave of digital transformation and disruption is coming at us fast. Many organizations see this wave as a threat and experience stress, but there are also organizations that just see this wave as an opportunity.

Imagine sitting with just 10-15 fellow executives at a premier location, gaining clarity on the impact of AI on your industry while enjoying an exquisite dining experience. These are not just meetings—they are transformative moments that will shape the future of your organization

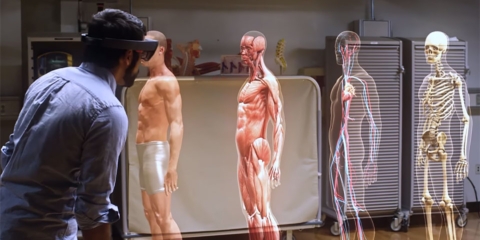

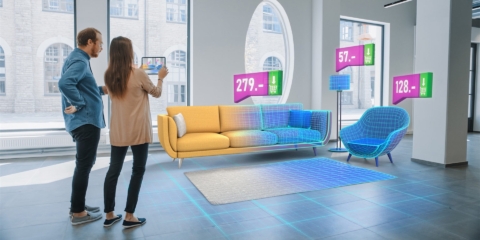

In the future, 3D printing and generative design will allow for products to be designed in a more decentralized manner, and production will take place closer to the customer and fully on-demand. 3D printing technology will also allow for more customization and personalization of products.

The agricultural industry is ripe for disruption. Robotics, AI, and IoT are all technologies that have the potential to radically transform the way we grow food. In combination with vertical farming, these technologies could increase the efficiency and quality of agricultural products.

A human-centered society is one that puts people first and where technology is used to unite and empower people. It is a society that values biological life and dignity above all else. It is a society that recognizes the importance of human relationships and works to strengthen them. In a human-centered society, all members of the community are valued and treated with respect.

The future of healthcare is here. New technologies like AI, IoT, big data, and smart sensors make it possible to become the CEO of your own health. Imagine that your phone can listen to your voice and AI algorithms can detect small nuances in the tone of your voice that indicate specific diseases.